Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

You might notice a puddle of dark fluid forming on your garage floor, or perhaps the dreaded "Low Oil Pressure" warning light flickers on during a cold start. For many vehicle owners, these symptoms lead to a confusing diagnosis: a cracked or leaking oil filter housing. This component is no longer just a simple lid for your filter; it has evolved into a sophisticated "control center" for your engine's lubrication system.

Modern engines have shifted away from the traditional spin-on metal cans we used for decades. Today, manufacturers utilize cartridge-style systems integrated into a complex housing that manages filtration, cooling, and sensing. While this design offers environmental benefits, it introduces new failure points that can lead to catastrophic engine damage if ignored.

This article goes beyond the basic definition. We will help you evaluate the specific symptoms of failure, understand the trade-offs between OEM plastic and aftermarket aluminum upgrades, and analyze the return on investment for a complete assembly replacement. Understanding these factors ensures you solve the leak permanently rather than paying for the same repair twice.

Role Complexity: Modern housings often integrate oil coolers, bypass valves, and sensors, making them critical for thermal management, not just filtration.

Material Weakness: The primary cause of failure is thermal cycling (heating and cooling) causing plastic housings to warp or crack over time.

Diagnostic Precision: Leaks are often misdiagnosed; distinguishing between a failed gasket, a cracked housing, or a leaking oil cooler is vital for cost-effective repair.

Replacement Strategy: Due to high labor intensity (location), replacing the full assembly is often more economical long-term than replacing gaskets alone.

To understand why this component fails, you must first understand what it does. In older vehicles, the oil filter adapter was a simple metal block bolted to the side of the engine. Today, the oil filter housing is a multi-functional assembly that acts as the traffic controller for your engine's lifeblood.

Manufacturers have transitioned to complex assemblies that route oil between the engine block, the filter element, and heat exchangers. This design creates a "Kidney Loop." The housing diverts dirty oil from the oil pump, forces it through the filter media, and then routes the clean oil to critical bearings and lifters. This centralization simplifies engine packaging but increases the stress placed on a single component.

The housing is more than a plastic shell. It contains several precision-engineered sub-components that are vital for engine safety:

The Bypass Valve: This is a fail-safe mechanism. If you neglect maintenance and the filter becomes completely clogged with sludge, this valve opens. It allows dirty oil to bypass the filter and circulate through the engine. While dirty oil is not ideal, it is preferable to oil starvation, which would seize the engine in seconds.

Sensor Ports: Modern Engine Control Units (ECUs) require real-time data. The housing typically features threaded ports where oil pressure and temperature sensors mount. These sensors communicate directly with the computer to regulate timing and warn the driver of anomalies.

Integrated Oil Coolers: Many designs feature a "sandwich" configuration where an oil cooler bolts directly to the housing. Coolant flows through one side of the plates, and oil flows through the other. This facilitates rapid warming of the oil during cold starts and cooling during heavy operation. However, it also introduces the risk of cross-contamination if internal seals fail.

The shift toward these permanent housings was largely driven by environmental concerns. Traditional spin-on filters create massive amounts of metal waste because the steel canister is discarded with every oil change. The modern housing system uses a replaceable paper or synthetic cartridge. This reduces hazardous waste, but it means the housing itself remains on the engine for the vehicle's lifespan, subjected to years of relentless heat and pressure.

Despite their sophisticated design, these components are notorious for failing between 50,000 and 100,000 miles. The failure is rarely due to impact or abuse; it is a matter of physics and material science.

Most automotive manufacturers, including those making the ubiquitous Pentastar V6 or various European engines, utilize glass-filled polymers (typically PA66 nylon) for these housings. This material is lightweight, inexpensive to mold, and resistant to chemicals.

However, it suffers from a phenomenon known as Thermal Cycling. Every time you drive, the engine heats the plastic to over 200°F (93°C). When you park, it cools to ambient temperature. Over years of expansion and contraction, the plastic loses its plasticity and becomes brittle. Eventually, microscopic fissures form, typically near the mounting base or sensor ports, leading to structural cracks that spew oil.

The seals between the housing and the engine block are typically molded rubber O-rings or figure-8 gaskets. Rubber requires elasticity to maintain a seal against pressurized fluid. Over time, heat exposure causes "compression set." The rubber flattens out, loses its ability to push back against the mating surface, and allows pressurized oil to escape. This often happens before the plastic itself cracks, but the symptoms look identical.

Human error accelerates failure rates significantly. During routine maintenance, mechanics or DIY enthusiasts often overtighten the plastic filter cap. Because the cap threads directly into the main housing, excessive torque transfers stress fractures down into the housing body. Once the threaded neck cracks, the entire assembly is compromised.

It is crucial to differentiate the failure mode. If the plastic housing cracks externally, you will see oil leaking onto the engine or ground. However, if the internal gaskets mating the oil cooler to the housing fail, fluids may mix internally. This results in oil entering the cooling system (or vice versa), which is often misdiagnosed as a blown head gasket.

Accurate diagnosis saves money. You do not want to replace a head gasket when the problem is a $200 housing assembly. Use this logic to pinpoint the issue.

Finding the source of the leak can be tricky because gravity pulls oil downward and airflow pushes it backward.

The Valley Test: On V6 and V8 engines, the oil filter housing usually sits deep in the "valley" between the cylinder banks. If the housing fails, oil pools in this valley before overflowing down the back of the engine and onto the transmission bellhousing. If you see a pool of oil sitting under your intake manifold, the housing is the prime suspect.

The Belt Test: On engines where the housing is front-mounted, leaks often drip onto the serpentine belt. This flings oil throughout the engine bay, damaging hoses and the alternator. A concentric line of oil spray on the underside of your hood often points to a front-mounted housing leak.

| Symptom | Likely Culprit | Urgency |

|---|---|---|

| Oil Puddle on Ground | External Housing Crack or Gasket Failure | High (Fire Risk) |

| "Milky" Coolant (Mayonnaise look) | Internal Cooler Gasket Failure | Critical (Engine Damage) |

| Low Oil Pressure Warning | Bypass Valve Failure or Massive Leak | Immediate Stop |

| Oil Splatter on Alternator | Front-Mounted Cap/Housing Seal | Medium (Electrical Risk) |

When ordering parts, you might encounter confusing terminology. Parts catalogs may list this component as an "Oil Filter Adapter," "Filter Stand," or "Housing Assembly." In older vehicles, an adapter was a separate piece. In modern cars, these terms are often used interchangeably for the main unit. Always verify the part using your specific VIN to ensure the port configuration matches your engine's sensors.

If you confirm your housing has failed, you face a choice: replace it with another plastic Original Equipment Manufacturer (OEM) unit or upgrade to an aftermarket aluminum version.

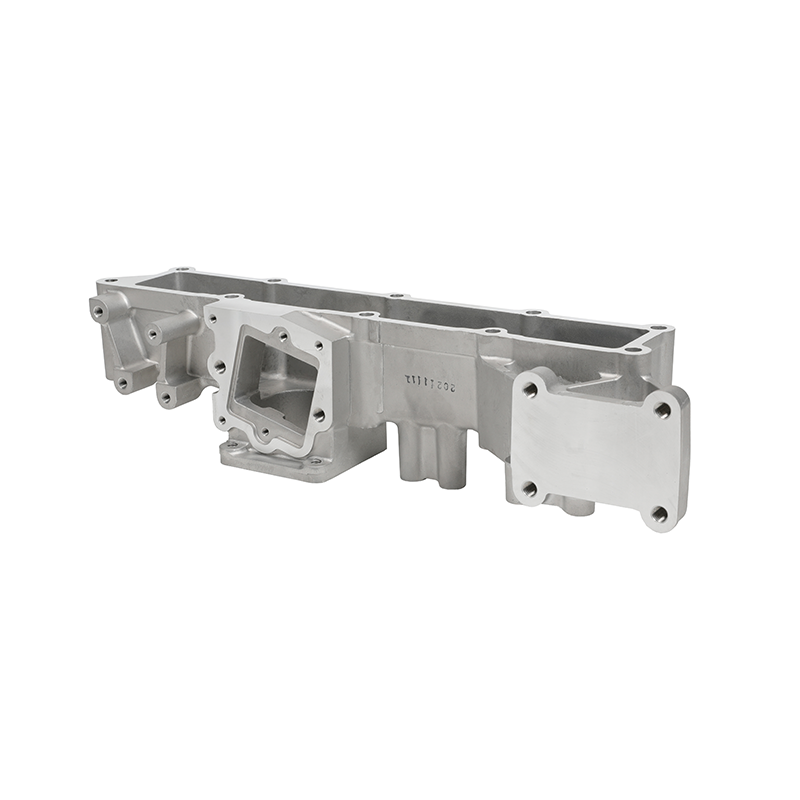

The aftermarket has responded to the "plastic problem" by CNC machining or casting aluminum replacement housings. Theoretically, these solve the cracking issue permanently because aluminum handles thermal cycling far better than nylon.

Before buying the shiny metal upgrade, consider these factors:

Durability: Aluminum is undeniably superior in resisting cracks. It will not become brittle after 50,000 miles of heat cycles.

Tolerance and Fitment: This is the weak point of aftermarket aluminum. Cheap castings often have poor machining tolerances. If the surface where the sensor mounts is not perfectly flat, or if the threads are rough, the new unit will leak immediately. OEM plastic units are injection molded to exact specifications, guaranteeing a perfect fit every time.

Thermal Expansion: Engineers design engines with specific expansion rates in mind. An aluminum housing expands at a different rate than the iron or aluminum block it bolts to. This differential expansion can stress the gaskets or bolts differently than the original plastic design intended.

For most daily drivers, a high-quality OEM plastic unit is the safest bet. It typically lasts 60,000 to 100,000 miles and guarantees leak-free fitment. However, if you are a performance enthusiast or use your vehicle for heavy towing (high heat), a high-quality aluminum unit from a reputable manufacturer—like Altop Die Casting—may offer better long-term reliability, provided you verify the casting quality.

The cost of this repair is often 80% labor and 20% parts. This ratio dictates your repair strategy.

Vehicle owners often attempt to save money by replacing only the gaskets (the rubber O-rings), which cost under $20. This is frequently a false economy. To access the housing, you typically must remove the upper and lower intake manifolds, fuel rails, and injectors. This labor takes 3 to 5 hours.

If you replace only the gaskets on an old plastic housing, the plastic itself is likely already brittle. It may warp or crack just 5,000 miles later, forcing you to pay the expensive labor costs all over again.

Recommendation: If the vehicle has over 60,000 miles, always replace the full assembly (Housing + Oil Cooler + Sensors). The incremental cost of the parts is negligible compared to the risk of repeating the labor.

Parts Cost: A full OEM assembly typically ranges from $150 to $300. Aftermarket kits can be cheaper ($80-$150) or more expensive for billet aluminum ($300+).

Labor Cost: Expect 3 to 5 hours of labor. At standard shop rates, this totals $400 to $800.

"While You're In There": maximize your ROI by performing overlapping maintenance. Since the intake manifold is off, replace the spark plugs, ignition coils, and intake manifold gaskets. This saves you hundreds of dollars in future labor.

If you perform this repair yourself, precise torque is non-negotiable. Plastic housings usually require low torque settings, often measured in inch-pounds, not foot-pounds. Over-torquing the mounting bolts will crack the new housing instantly. Furthermore, you must pre-lubricate all new O-rings with fresh oil before installation. Installing a dry O-ring can cause it to pinch or tear, resulting in an immediate leak upon startup.

The oil filter housing is an unsung hero of modern engine management, coordinating filtration, cooling, and sensing in a hostile environment. While the transition to plastic materials has introduced issues with thermal fatigue, understanding the symptoms allows for early intervention.

For the vast majority of vehicle owners, a leak in the engine valley or oil in the coolant should be treated as a signal to replace the entire housing assembly. Attempting to patch leaks with gaskets or sealants is a temporary fix that risks catastrophic oil loss. By choosing the right replacement part—whether a new OEM unit or a high-grade aluminum upgrade—and respecting torque specifications, you can ensure your engine remains lubricated and cooled for another 100,000 miles.

Check your specific part number by VIN today, and if you spot oil drops on your driveway, inspect your engine valley immediately.

A: No. A cracked housing can leak oil onto hot exhaust components, posing a significant fire hazard. Additionally, rapid oil loss can lead to low oil pressure, causing internal engine bearings to seize. If the leak is internal (coolant mixing), driving can destroy your engine bearings and cooling system simultaneously.

A: This symptom usually indicates a failure of the internal gasket separating the oil and coolant channels within the housing or the attached oil cooler. Since oil pressure is higher than coolant pressure, oil is forced into the cooling system, creating a milky sludge in your reservoir.

A: Professional mechanics typically require 2 to 4 hours. The time is mostly spent removing components that block access, such as the upper and lower intake manifolds, fuel injectors, and vacuum lines. The actual swapping of the housing takes only minutes once exposed.

A: It depends on your priorities. Aluminum housings offer superior durability against cracking but can suffer from poor manufacturing tolerances in cheaper aftermarket kits. OEM plastic housings guarantee perfect fitment and sensor accuracy but will likely need replacement again after 60,000–100,000 miles due to thermal fatigue.

A: The housing is the mounting point for the filter and sensors. The oil cooler is a heat exchanger often bolted to the housing. In many modern vehicles, they are sold as a single pre-assembled unit because they share sealing surfaces and are difficult to separate without causing leaks.